/ ALUMINIUM TUBES

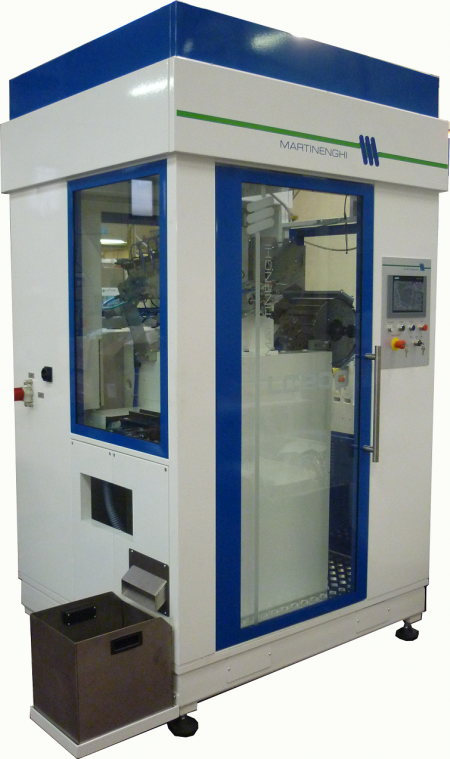

Leak Control Machine LC200

The machine takes full advantage of the innovative conveying system made of two independent holders rotating in a coordinated way, each driven by a toothed belt moved by a brushless motor. On each holder two segments are fitted at 180°, each with eight seats, able to hold the tubes during the working operations.

The sophisticated motion of these segments, responding to the various timings required by the different process functions (continuous loading-unloading and discontinuous monitoring of the cans) is achieved through inverters controlled by PLC.

The resulting motion of the segments allows to loading and unloading of tubes at line production speed, while it makes it possible to test tubes when they are standing in the fixed monitoring station for the time required.

The control station is made up of 8 pressure gauges, fed by a pneumatic circuit equipped with pressure controls, flow capacity and air filtering. The gauges are mounted on a sliding support, equipped with heads and gaskets.

During testing operations, these heads close the tubes and blow air inside, while the gauges check the pressure values, which are then compared with the reference values memorized in the PLC of the machine. The tubes which do not comply with standard values are blown off from the downloading drum.