/ ALUMINIUM TUBES

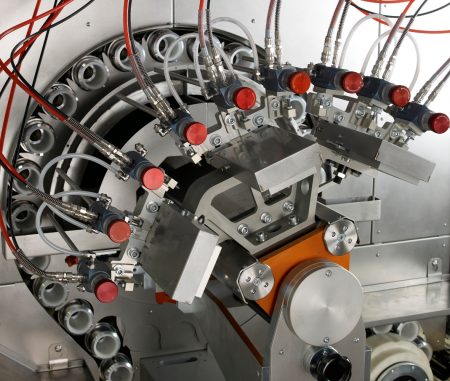

Internal Lacquering Machine VX9

The VX9 Internal Coating Machine represents the benchmark for internal lacquering of tubes, aerosol cans and cylindrical containers.

Thanks to its 9-guns configuration with triple spraying on each piece, the machine is able to reach high production speeds with low reciprocating motion. Both chain and guns are driven by two independent, synchronized "brushless" motors.

The "Easy Control" system - with independent controls for varnish needle aperture and varnish nebulisation air, allows spray adjustment while the machine is running. This is controlled by means of a microprocessor with adjustment of start and stop spray by selecting each single gun digitally and independently.

The new exhaust system has been greatly improved to optimize over-spray elimination from work area. Access for inspection has also been improved to facilitate cleaning and maintenance operations as well as to change filtering device.

Outstanding accessibility from all sides of the machine and its ergonomic design allow quick changeover and easy maintenance operations.

While the machine is running it is possible to automatically select and safely extract any single tube/can for quality inspection.

Easy format change operations allow greater flexibility and adjustability to the single production requirements. The customizable touch screen control panel allows easy “tuning-up” operations to be carried out by the operator.

As with all Martinenghi Tech machines, also the VX9 is equipped with a remote diagnostic system.